Customised Hermetic

Solutions for

harsh environments:

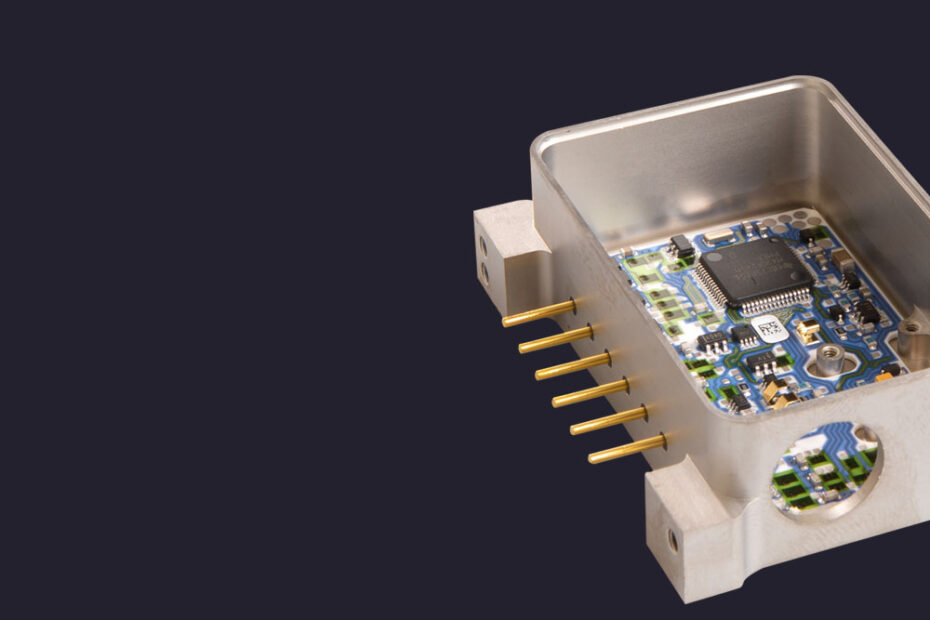

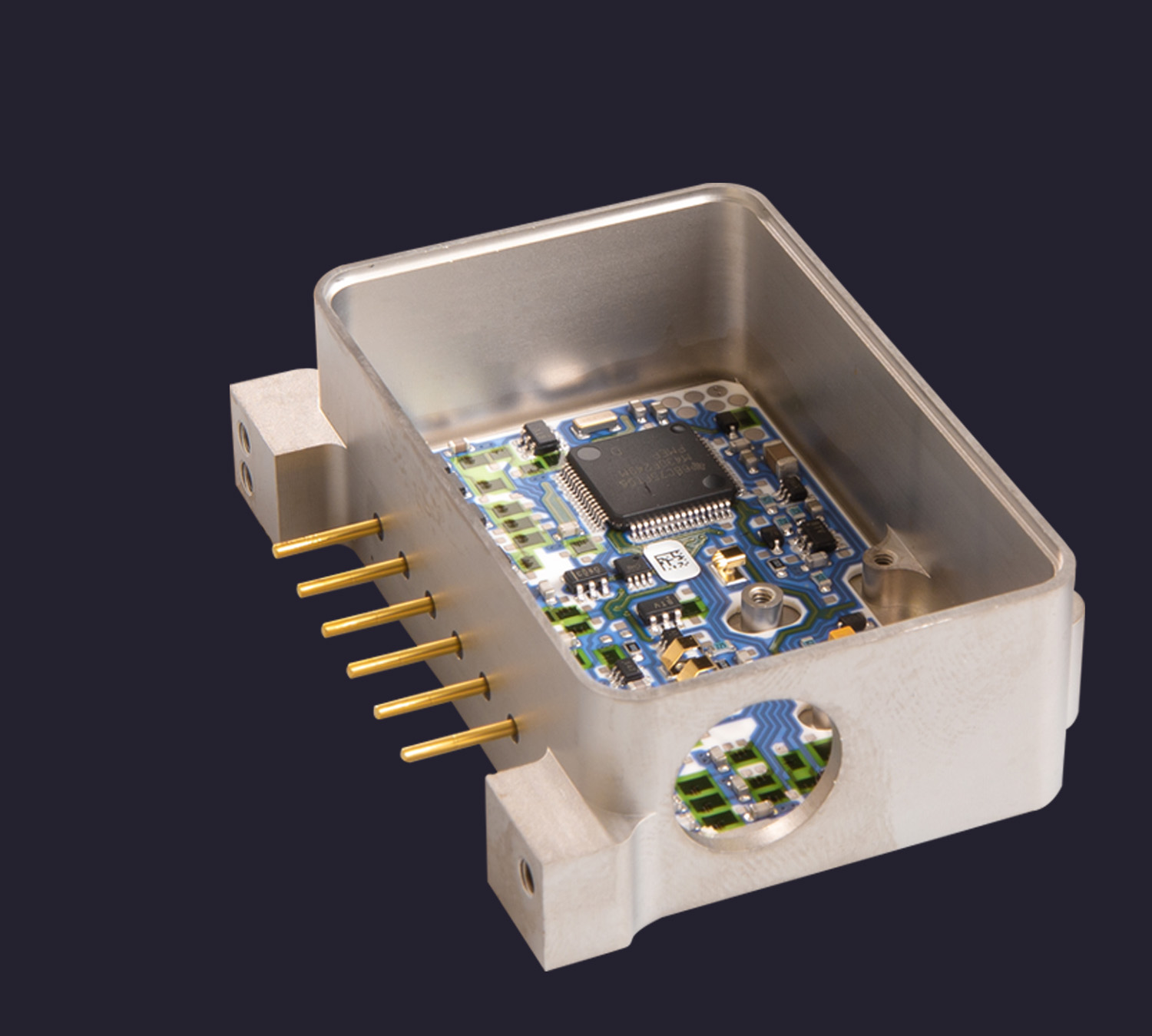

C-MAC developed different solutions to assure highest quality in hermetic solutions for it’s customers. A combination of ceramic substrate with a hermetic sealed solution to protect the circuit from its aggressive environment is a popular choice.

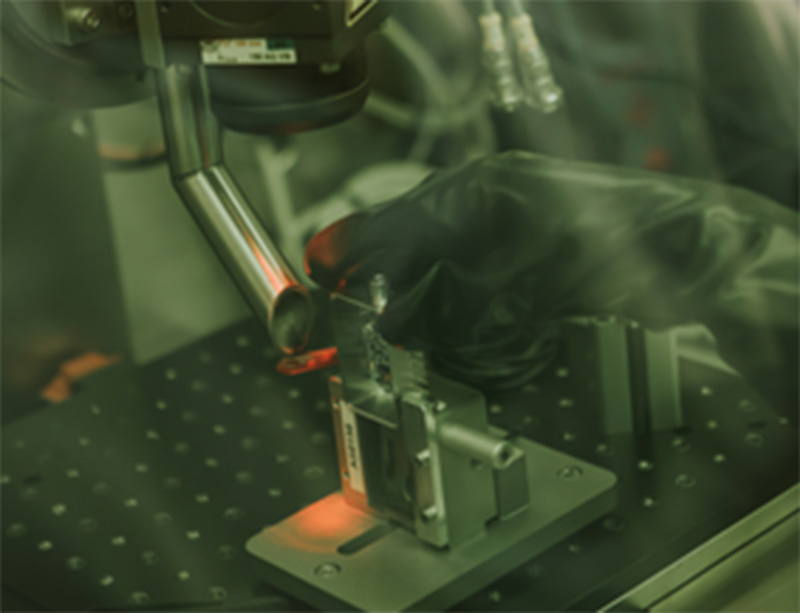

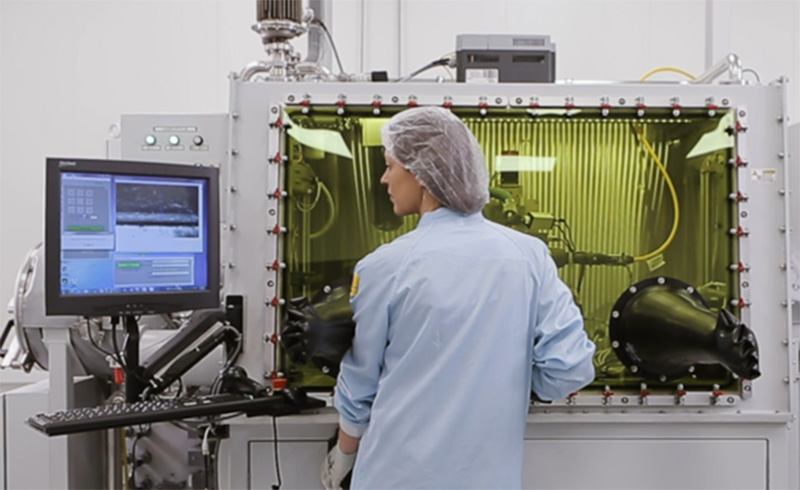

As ceramic is air and liquid tight, the substrate can be part of the enclosure; in that case a cap is soldered under specific conditions on the unit with an air & liquid tight solderjoint. This provides an economical and reliable solution. By doing this in a vacuum reflow oven, we can also assure an inert gas under the encloser which will avoid humidity and thus corrosion over time. In other applications, the circuit is glued or soldered in a housing which is closed hermetically with laser in a glove box after vacuum bake out. Inside the glove box, a mixture of noble gasses is guaranteed to assure a long lifetime of the circuit inside by avoiding any moisture that could degrade the part. A preferred solution for the enclosure is often stainless steel, as this material resists well to aggressive media. Other solutions such as aluminium and kovar are also possible. One more solution for hermetic seal with ceramic parts can be a glass-seal, which is cured at higher temperatures (400-600°C) to assure under extreme temperatures also a reliable interconnection. Typically, this is done to build economical and reliable pressure sensors or to seal a ceramic cap onto a substrate.

Extensive

Experience

+ 10 years providing hermetic solutions with guaranteed superior performance, stable under extreme temperature and aggressive environments

Leading Process

Capabilities

State of the art vacuum soldering ovens and glove box with laser for stainless steel under controlled atmosphere

Supply Chain

Management

Extensive supplier relations, Competitive & Reliable, Experience with VMI, KANBAN, JIT and flexible to adapt to specific customer needs

Our solution engineers are here to help

Navigating challenges, delivering solutions

Frequently

Asked

Questions

Today we weld stainless steel, can discuss other materials if required.

Today we solder, glass seal and laser weld to obtain hermetic solutions

We can provide 2D & 3D AOI, X-ray, Flying probe, ICT & functional testing

Helium test to detect fine leaks and bubble test to detect big leaks. Detection levels:

- Industry: 1.10-8 atm.CC/s Helium

- Avionics: 5.38×10-9 atm.CC/s helium

Automotive; IATF16949; Medical: ISO-13485; Aerospace: EN 9100

We can accommodate gold, aluminium etc wire bonding, see specific section for detailed capabilities

We can provide Automated & Non-Automated T&R, Custom Trays etc