Manufacturing Experts

for Power Electronics

Solutions:

For more than 10 years, C-MAC is building custom power parts and modules. Providing a dedicated solution, guaranteeing the best performances in the smallest possible packaging, is a key element in all our solutions.

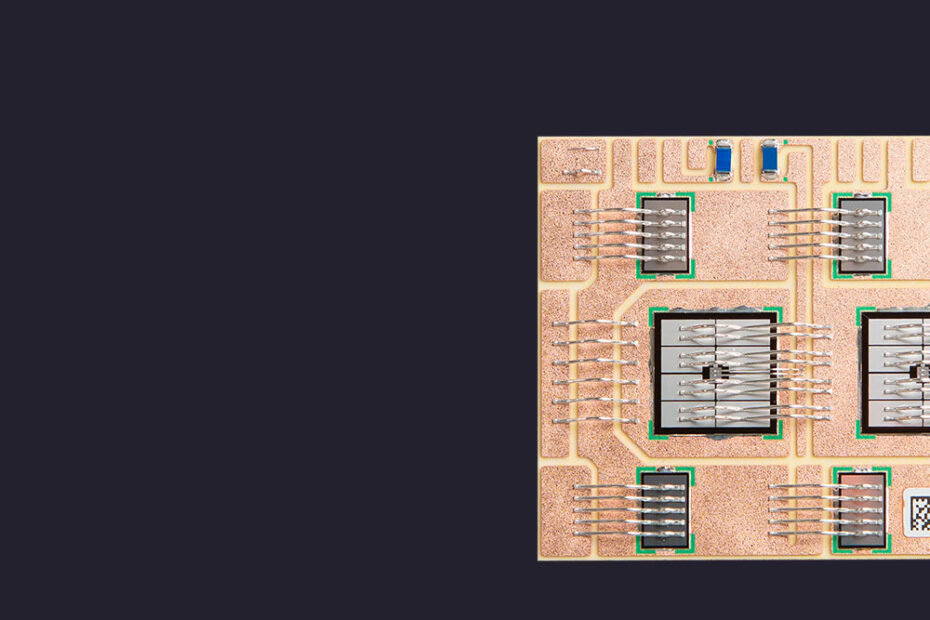

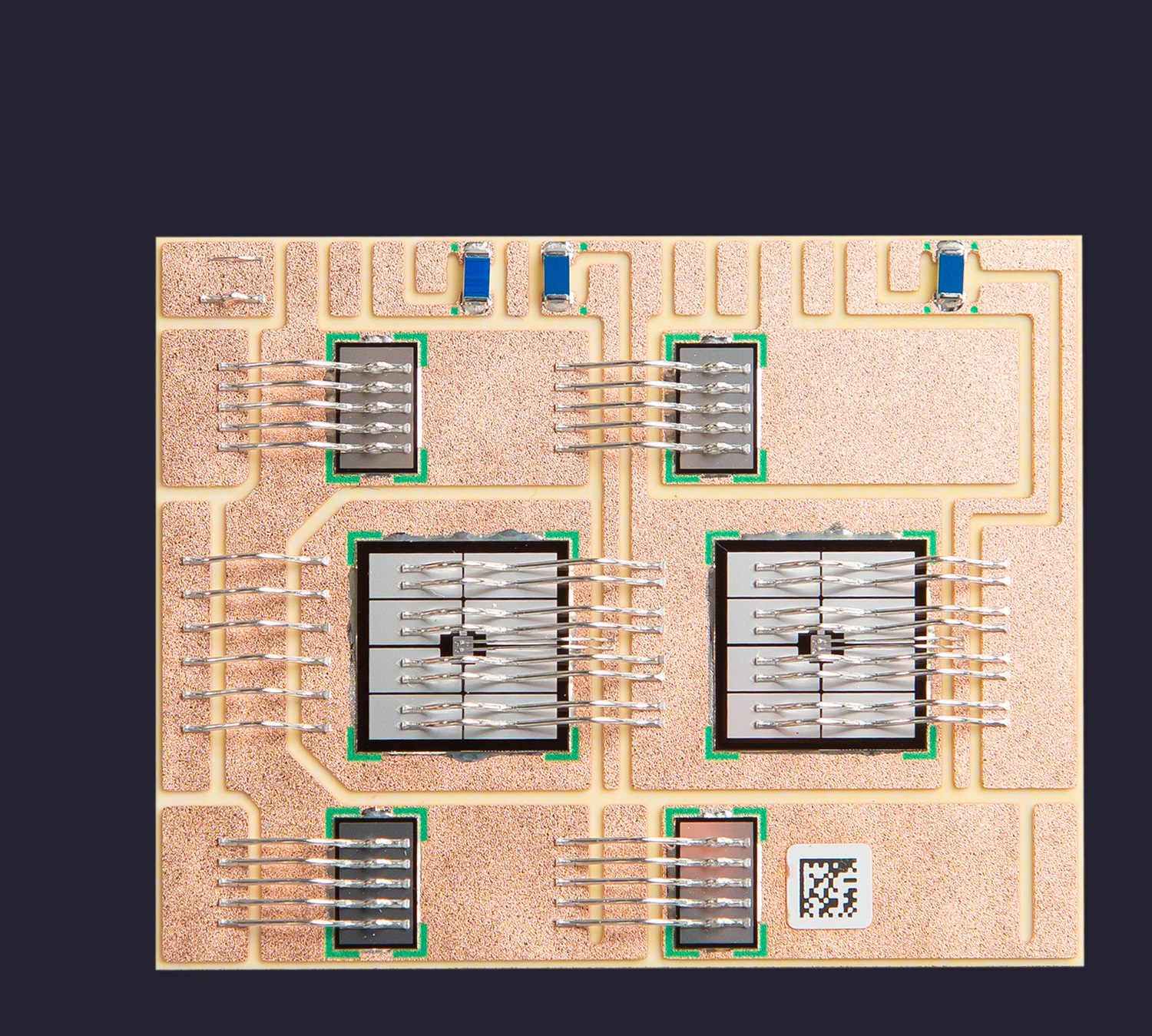

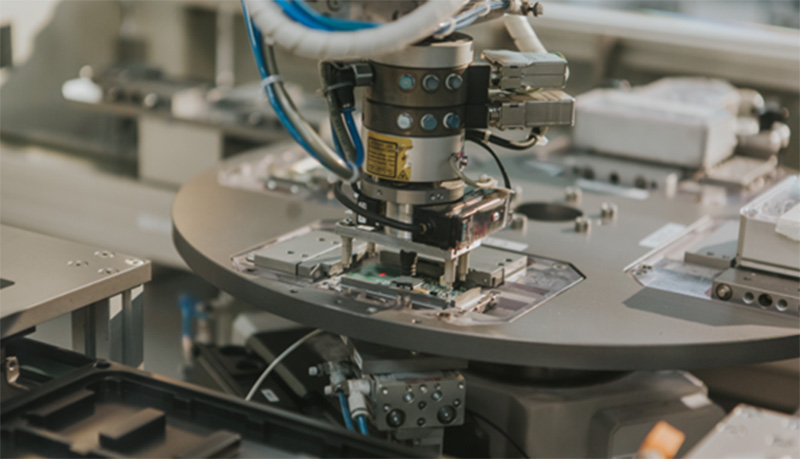

Power modules can be based on DBC (Direct Bonded Copper substrates), AMB (Active Metal Brazed substrates) IMS (Insulated Metal Substrates), Standard & Power PCB or Thick film. Thick film substrates are produced inhouse, other carriers are sourced from qualified sources on the market. We use as well discrete components as ‘chip & wire bonding’ technology. C-MAC has 2 fully automated lines for vacuum soldering for single sided ceramic boards (DBC, AMB, thick film) All alu thick wire options are available, going from 125µm to 500µm. C-MAC can supply semi-finished products (assembled boards without housing, which are shipped in dedicated trays to the customer) as well as complete finished and tested modules. Applications are based on mosfets with classic Si (silicium), GaN (Gallium Nitride) or SiC (Silicon Carbide) technology, depending on customer needs. More recently we also invested in new Selective Soldering lines to support new designs for power converters used for various e-mobility applications.

Extensive

Experience

Last 10 years millions of power boards in automotive with 0 ppm strategy. Power Module for ESA new Ariane 6 rocket qualified. Developments ongoing for avionics

Leading Process

Capabilities

Fully automated vacuum assembly lines with SPI/AOI/Xray in line. Automated thick wire bonding. End of line power testing & aging. Selective Soldering for power converters used in various e-mobility applications

Supply Chain

Management

Extensive supplier relations, Competitive & Reliable, Experience with VMI, KANBAN, JIT and flexible to adapt to specific customer needs

Our solution engineers are here to help

Navigating challenges, delivering solutions

Frequently

Asked

Questions

From a few hundred/year (modules) up to > million for assembled boards

Testing is in most cases customised and we work together with leading companies for dedicated power testers where the machines are build to specification. So far we can test up to 1500V/1mA breakdown voltage and 200A/10V power testing.

All possible options from inhouse printed thick film substrates to DBC, AMB, IMS, Power PCB …

We provide both manual & automated singulation options

We can provide 2D & 3D AOI, X-ray

Automotive; IATF16949; Medical: ISO-13485; Aerospace: EN 9100

Soft silicone gel is applied into the housing under vacuum conditions and depending on volume in semi-automatic or manual way.

Unit traceability is assured by lasering or labelling the modules at the end of the line.