Providing High

Quality LED

Assemblies:

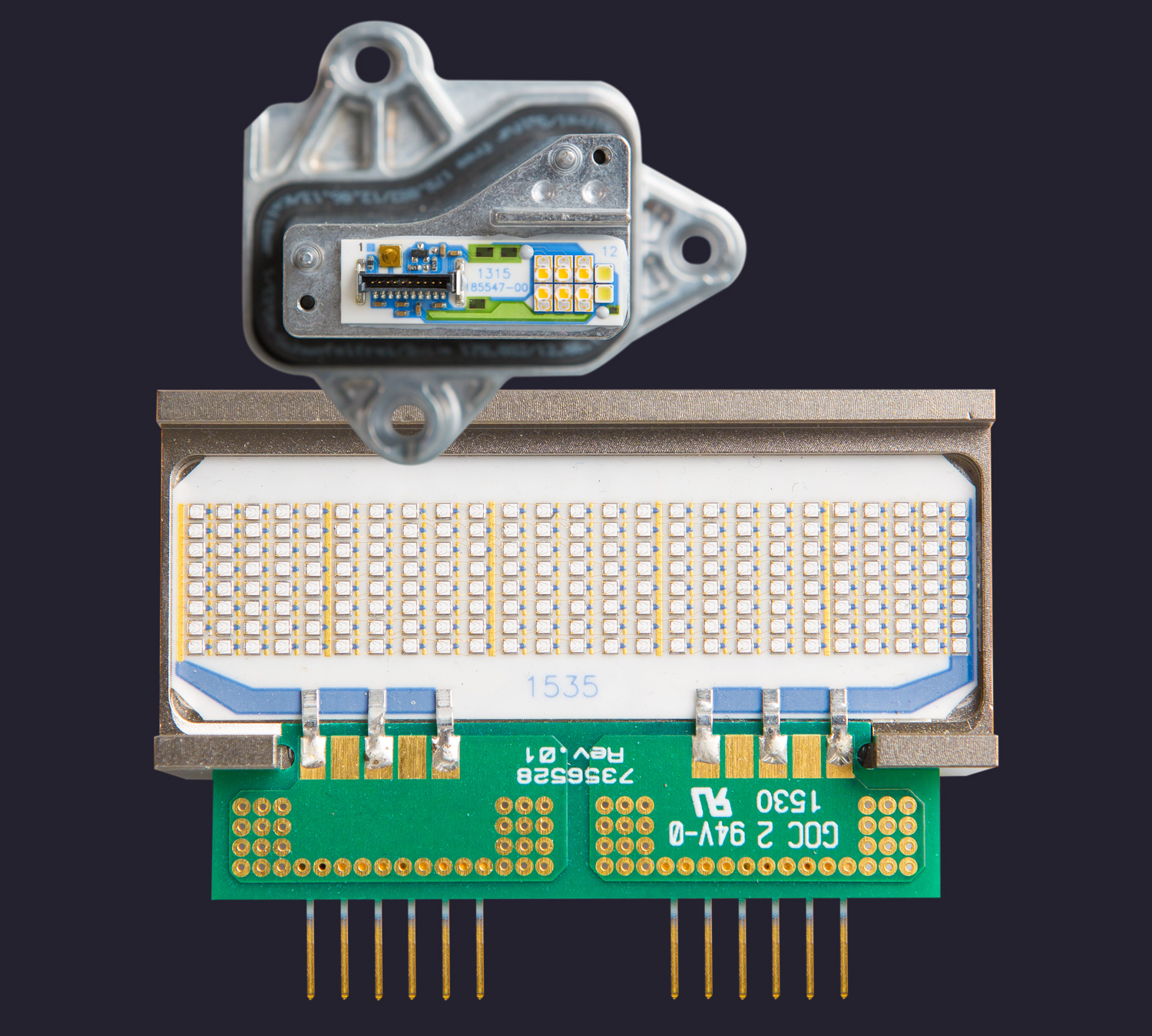

C-MAC has extensive experience with ceramic & pcb based solutions for LED lighting. When space is limited and heat needs to be removed, ceramic solutions come to the rescue.

The ceramic base will provide excellent heat dissipation and a uniform heat transfer whilst providing excellent matching of the LED die & substrate thermal coefficient. The reflectivity and electrical isolation of the base material are also excellent to deliver a final solution that is very cost competitive to special PCB solutions. We also handle a broad spectrum of other LED applications, from simple metallised substrates to complex water-cooled modules integrating hundreds of bare die LEDs.

Superior

Quality

Process, Testing, Inspection and Traceability according to IPC and major market standards

Leading Process

Capabilities

Ceramic circuit printing , State of the art SMT, Coating, various type of boards; chip on board

Design for

Manufacturing

Our engineering and process teams have extended experience to optimise your design for manufacturing

Our solution engineers are here to help

Navigating challenges, delivering solutions

Frequently

Asked

Questions

smt, leaded, bare die

Please contact our engineering team, this depends on the type of led & substrate

From Ceramic Substrates & PCB over metallised substrates to complex water-cooled modules

We have to capability to integrate hundreds of bare die LEDs.

We can provide 2D & 3D AOI, X-ray, Flying probe, ICT & functional testing.

Automotive; IATF16949; Medical: ISO-13485; Aerospace: EN 9100

We can accommodate gold, aluminium etc wire bonding, see specific section for detailed capabilities.

We can provide Automated & Non-Automated T&R, Custom Trays etc