Experienced partner

for Chip & Wire

bonding:

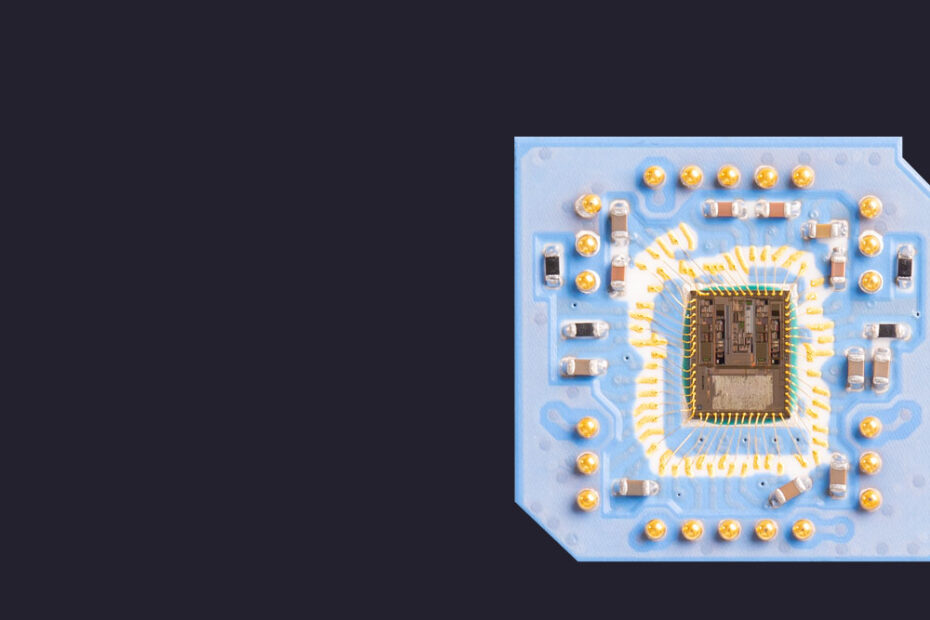

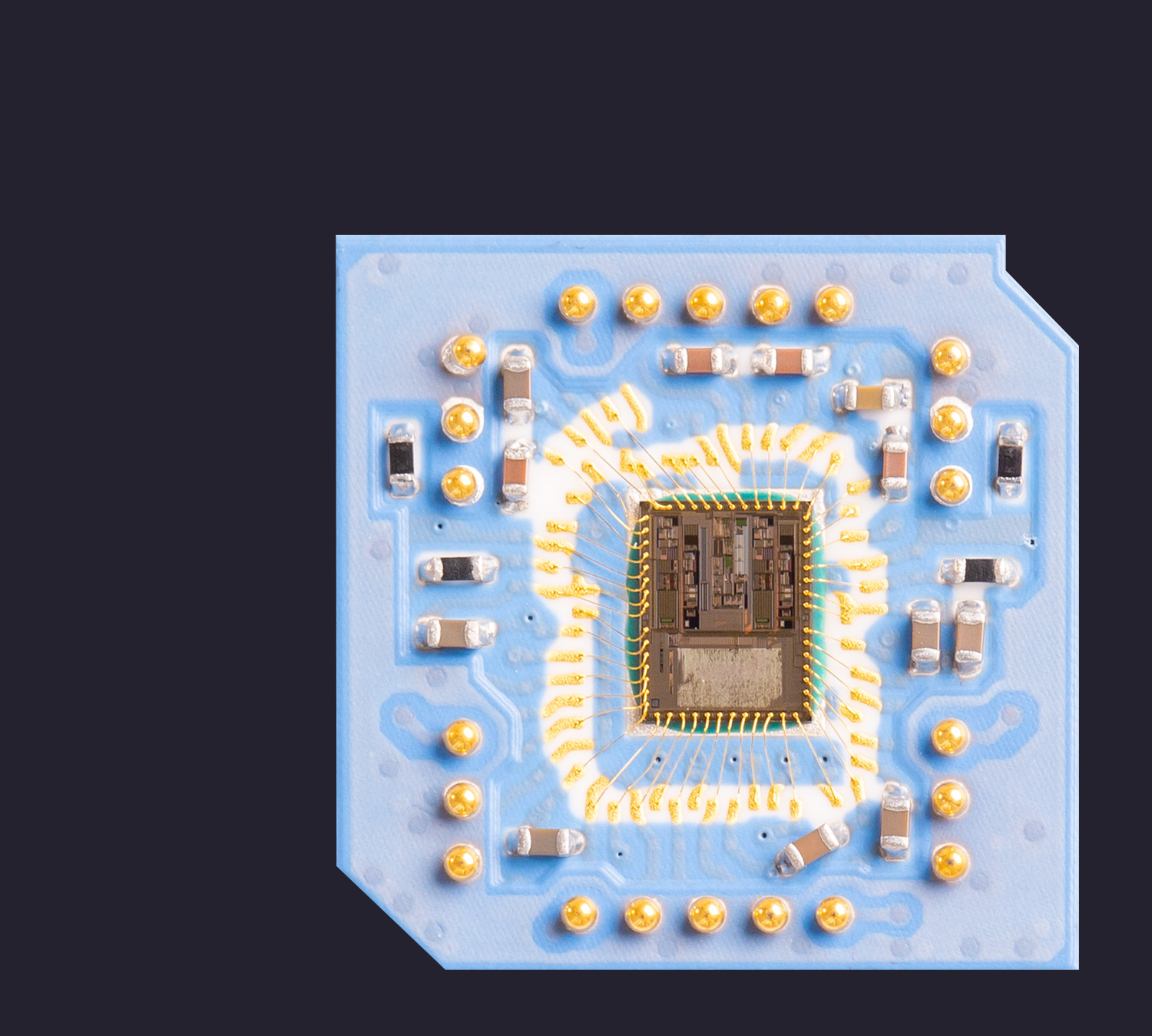

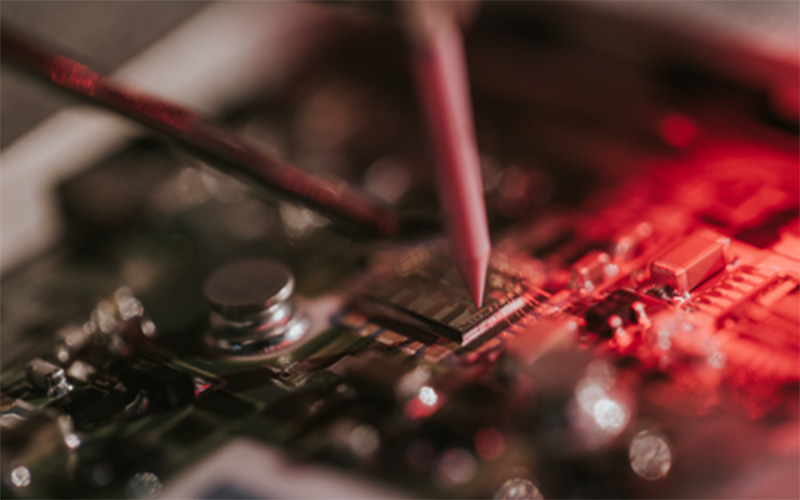

25 years of experience combined with state-of-the-art equipment makes us your ideal partner for all your projects that require chip & wire bonding.

We can perform chip & wire bonding on PCB, DBC or ceramic substrates but also interconnect your electronics board with your module housing if required. It is equally possible to add an hermetic enclosure (ceramic or metal). Depending on your application, we can bond with either gold (Au) or aluminium (Al) wire. Electrical requirements will determine if thin or thick wire bonding will be applied. If required, we can protect the dies & bond wires with a glob top (epoxy or silicone) or a soft silicone gel. We can perform all these processes under our automotive, Aerospace & Medical market certifications

25 years of

experience

Combined with state-of-the-art equipment makes us your ideal partner for chip & wire bonding

Leading Process

Capabilities

We can bond both Gold & Aluminium, Thin & Tick wire and as well protect your Dies

Supply Chain

Management

Extensive supplier relations, Competitive & Reliable, Experience with VMI, KANBAN, JIT and flexible to adapt to specific customer needs

Our solution engineers are here to help

Navigating challenges, delivering solutions

Frequently

Asked

Questions

Gold wire 18-50µm wire diameter; Ball ball bonding; Stitch on ball; Secure bonding; Large surface (12″x6″); Deep access

Aluminium wire 18-50µm wire diameter; PiQC (Process Integrated Quality Control); E-box for controlled set-up

Aluminium wire 125-500 µm wire diameter; PiQC (Process Integrated Quality Control); All process data stored

PCB, DBC or ceramic substrates but also interconnect electronics board with module housing

We can provide 2D & 3D AOI, X-ray

Automotive; IATF16949; Medical: ISO-13485; Aerospace: EN 9100