Providing

High Quality

PCBA Solutions:

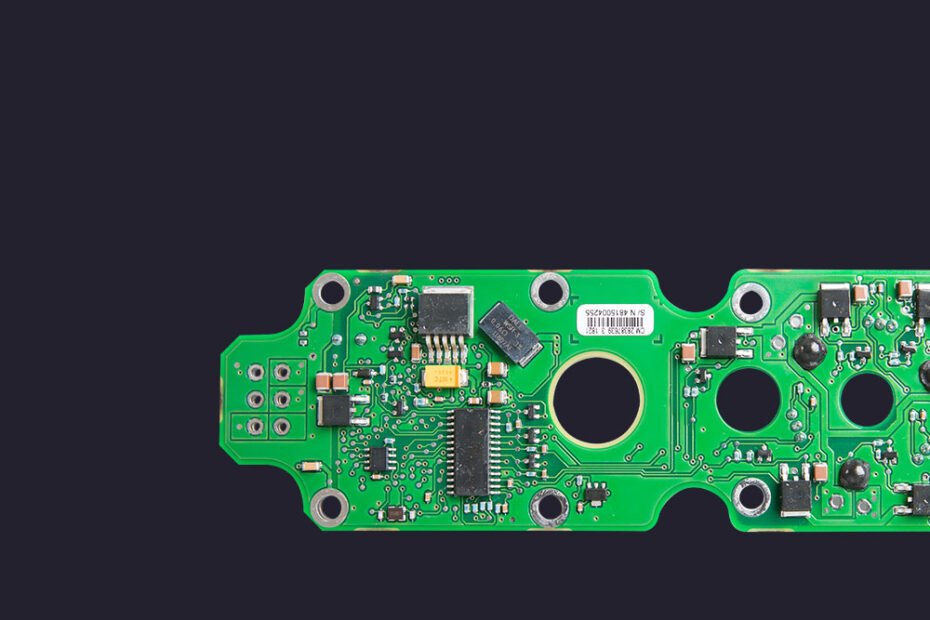

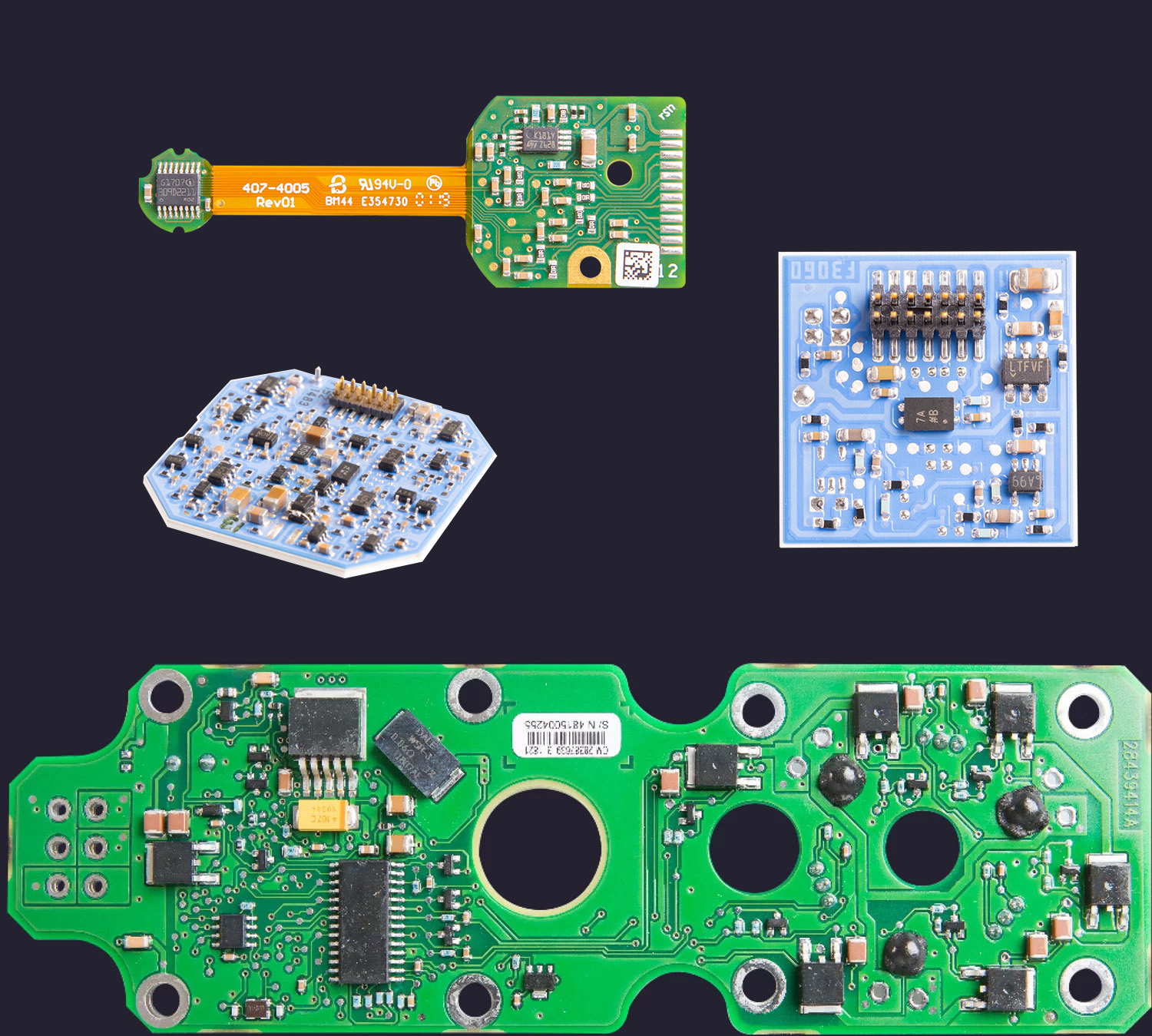

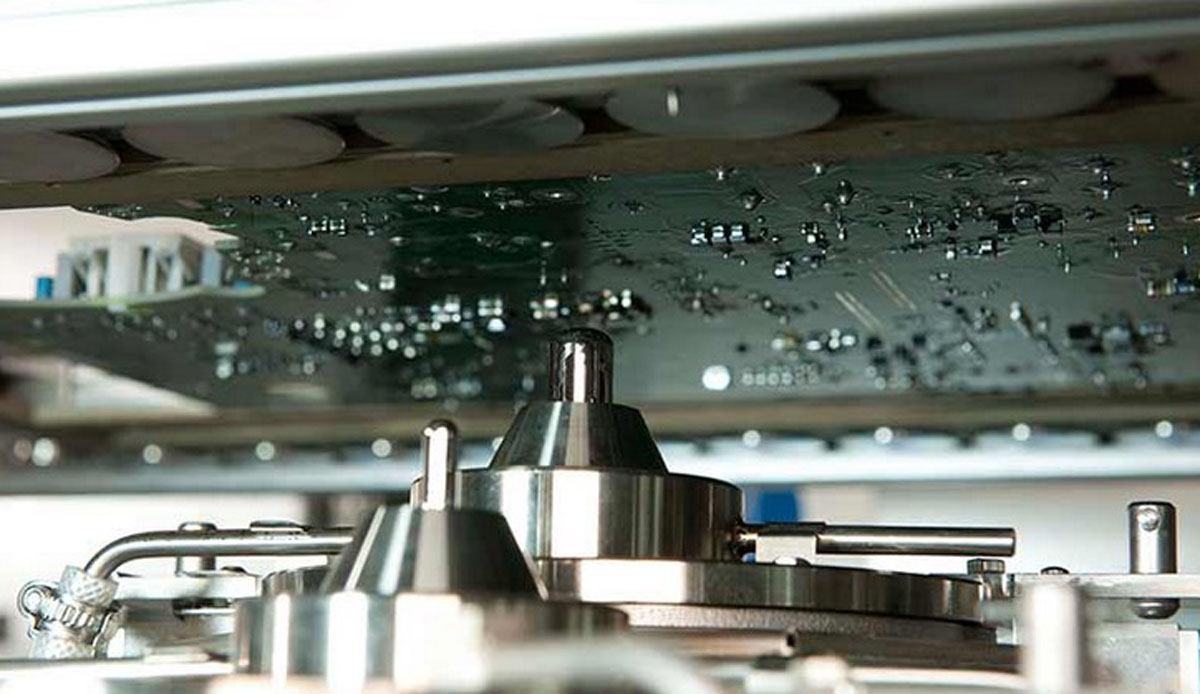

PCBA @ C-MAC means leading technology, state of the art PCB assembly and inspection equipment, strict quality testing and structured manufacturing processes.

We have extensive experience using most type of substrate materials including FR4, Flex Rigid Materials, DBC, IMS and of course our own Thick Film ceramic circuits. You can rely on our ‘Design for Cost’ ‘Design for Manufacture’ and ‘Design for Test’ services for the highest quality solutions at the lowest cost. All this in plants certified for Automotive, Aerospace & Medical markets

Superior

Quality

Process, Testing, Inspection and Traceability according to IPC and major Market Standards

Leading Process

Capabilities

Selective Soldering, State of the art SMT, Coating, various type of boards; chip on board

Supply Chain

Management

Competitive & Reliable , Experience with VMI, KANBAN, JIT and flexible to adapt to specific customer needs

Our solution engineers are here to help

Navigating challenges, delivering solutions

Frequently

Asked

Questions

01005 size

Largest board size for SMT=21’’ x 21; for selective soldering=14’’x14’’

Capacité combinée de tous les sites : 8 lignes de montage en surface (SMT), 4 lignes de soudure de composantes traversantes (THT).

Yes, we have selective conformal coating available

Automobile : IATF16949 ; Médical : ISO-13485 ; Aérospatial : EN 9100

We can accommodate gold, aluminium etc wire bonding, see specific section for detailed capabilities.

We can provide Automated & Non-Automated T&R, Custom Trays etc