Pioneers in Thick Film

Hybrid & Ceramic

Circuit Technology

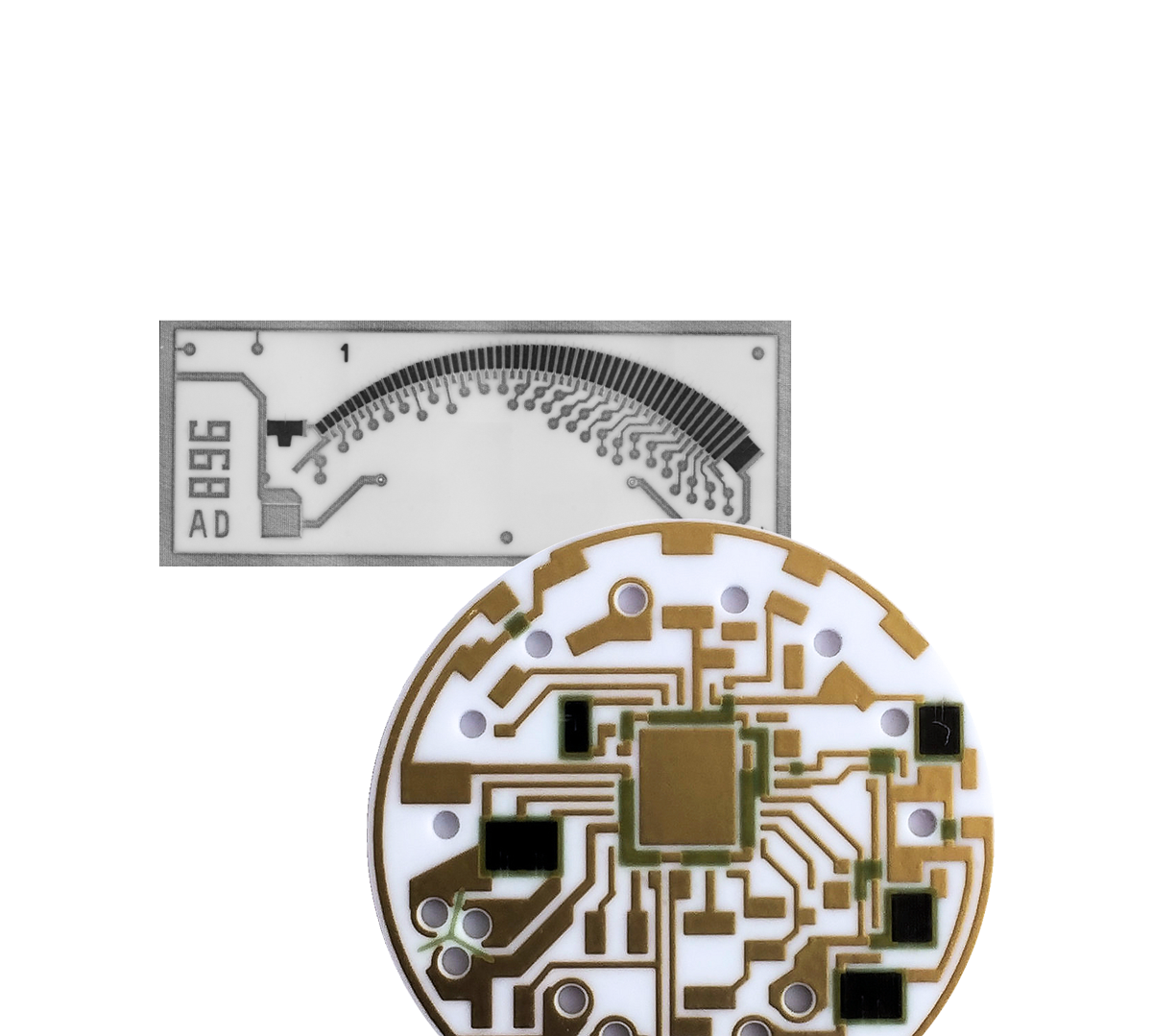

C-MAC is a global market leader in thick film hybrid & ceramic circuit technology, delivering high-performance ceramic PCB and thick film hybrid circuits for applications requiring exceptional reliability, thermal management, and electrical performance.

With over 50 years of unparalleled expertise, we provide end-to-end solutions for industries such as aerospace, automotive, medical, and industrial automation.

Explore our

capabilities

Compared to traditional FR4-based PCBs, Ceramic PCB offers superior performances, making them the ideal choice for high-reliability applications:

- High Thermal Conductivity – Efficient heat dissipation for high-power electronics.

- Extreme Durability – Resistant to temperature variations, moisture, and harsh environments.

- Precision & Miniaturization – Supports the integration of analog, digital, and power circuits on a single substrate.

- Exceptional Power Handling – Designed for applications requiring high current density and fast thermal response.

- Reliable Electrical Performance – Ensures consistent and long-lasting functionality.

These benefits make ceramic circuit boards the preferred choice for power electronics, sensors, and heating elements.

C-MAC invests in state-of-the-art equipment to deliver high-quality ceramic circuits with superior precision. Our cleanroom environment supports high-volume production with multiple substrate sizes.

Key Manufacturing Processes:

- High-Precision Screen Printing – Conductive, resistive, and dielectric pastes.

- Advanced Curing Systems – Ensuring long-term reliability and adhesion.

- Laser Trimming – For accurate resistor and circuit tuning.

- Automated Singulation – High-volume production efficiency.

- AOI Inspection & Functional Testing – Guarantees the highest quality standards.

With continuous investment in cutting-edge technology, our production capabilities evolve to meet the demands of advanced applications.

C-MAC offers a diverse selection of ceramic substrates and inks, allowing for optimized performance based on specific applications.

Available Ceramic Substrates:

- Alumina (Al₂O₃): Excellent thermal and electrical insulation.

- Aluminum Nitride (AlN): High thermal conductivity for power electronics.

- Silicon Carbide (SiC): Superior strength and thermal shock resistance.

Available Inks:

- Conductive Inks: Silver, gold, and platinum-based inks for high-reliability connections.

- Resistive Inks: Precision resistor pastes for stable performance.

- Dielectric Inks: High-performance insulating layers for circuit protection.

With strong supplier partnerships, we ensure reliable sourcing and customized solutions for your specific requirements.

How we can support

your next project?

Whether you need a single prototype or full-scale production, C-MAC is ready to deliver high-performance power module manufacturing solutions.

Why Partner

with C-MAC?

Partnering with C-MAC means:

- Proven Expertise: 50+ years in thick film hybrid & ceramic technology.

- End-to-End Solutions: From design to full-scale production.

- State-of-the-Art Facilities: Cutting-edge automation and quality control.

- Global Manufacturing: Facilities in Europe and North America.

- Custom Engineering: Tailored solutions for high-performance applications.